What is the production process of custom cardboard displays?

By Modernty Display Product Co.,Ltd

Oct 22, 2025

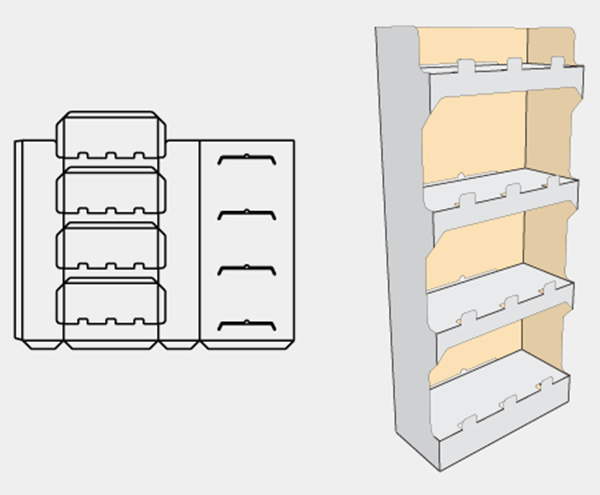

Design:

The design of the corrugated display requires the designer to be familiar with the 3D structure work, and the weight and volume of the goods should be considered to calculate the bearing capacity and space area of displays.

Sample:

POP displays generally use non-printed corrugated paper materials. According to the design structure drawing data, input the computer cutting sample machine, the sample cutting machine will make a standard flat paper shelf on the non-printed corrugated paper according to the indentation force and half-cut depth required by the structure drawing. The designer uses glue to paste and For other process processing, the next step can be done if the sample plate is made to match the design structure drawing.

Printing:

According to the graphic design draft of the paper display rack template, the film will be printed on the printing machine.

Post-process:

Printing colored paper over-gluing, mounting paper (printing paper + corrugated paper), over-oiling, indentation.

Packaging:

Semi-finished corrugated displays are assembled, reinforced, and then finished products are installed.

The prossess is

Design->Sample->Printing->Post-process->Packaging

Related Articles

-

How to Display Vape Juice Bottles: A Complete Guide to Boost Visibility and Sales?

When it comes to vape product presentation, display plays a pivotal role in attracting customers, conveying brand identity, and driving …

-

The Ultimate Guide to Customizing Your Tobacco Display Stand

Introduction If you sell tobacco products, your display stand is more than a shelf — it’s a silent salesperson. A …

-

How to Make a Display Stand from Cardboard

Display stand is a very useful tool for shopkeepers, retailers and other business owners. They are perfect for displaying an …

Trusted by These Featured Clients